Traditionally, Passenger Boarding Bridges (PBBs) are manually controlled and driven physically by operators at the control desk in the cabin.

Due to rising competition over the past two decades, airports are increasingly cutting costs which results in part-time and limited period contracts for airport workers, creating high staff turnover. Consequently, it is more and more challenging to recruit new team members, including qualified PBB operators.

ARCOS® provides numerous benefits including: Reduction in staff of up to 70% and creating value-added job positions that translates into decreased staff turnover whilst maintaining knowledge and skills, and minimisation of training costs.

Furthermore, a final significant advantage of ARCOS® is that its incorporated docking assistance allow operating times to be reduced by up to 20%.

Flight Plan Connection

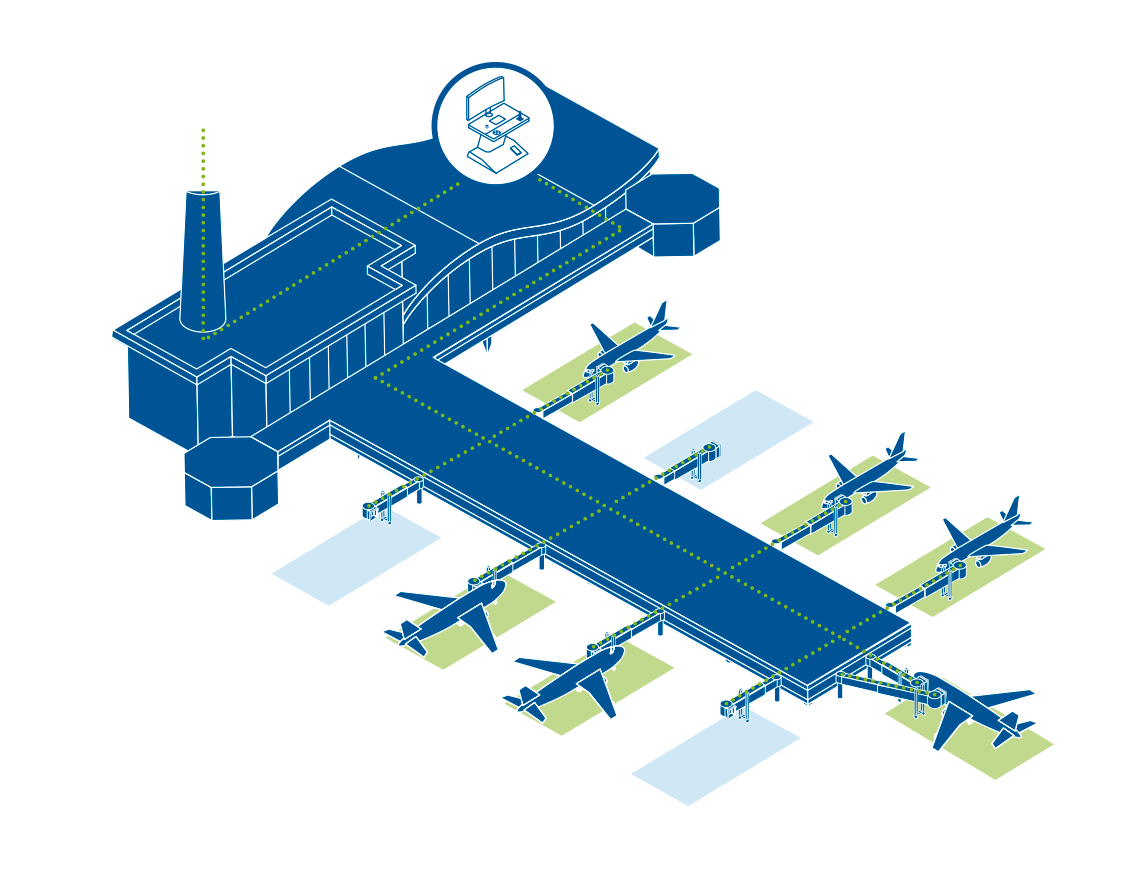

Flight plan schedules are sent in real-time to ARCOS® for complete workload management through the Smart Queue Management Module.

- The system updates in real time all data related to flight plans.

- The operator can see the daily flight plan programming on his desk screen.

- ARCOS automatically distributes the workload to each operator.

Ergonomic Desk

The system is installed in any department or office of the airport terminal. It does not take up much space and neither does it require complex installation.

- The desk includes all the regular controls of a real PBB desk.

- The desk is designed to comply with the ergonomic principles and recommendations established by UNE-EN 527-2:2017 and UNE-EN 11064-04:2013.

- The size and resolution of the ultra-wide monitor allows the operator to see multiple points of view during an operation. There is also an auxiliary touch screen on the desk for additional features, operating information, control settings, etc.

- The height-adjustable desk allows operators to change their working position between sitting and standing, thereby reducing operator fatigue.

Enhanced Security

The connection between the Apron and the ARCOS® system is complete, robust and secure.

- The 2CS of ARCOS® handles resource allocation and measures and monitors the latency time of the video system.

- Smart Queue Management Module, which guarantees optimization of resources and operations.

- Secure login for operators and for the Operations Director to manage the operators’ data.

Multi-camera System and Visual Aid

Thanks to the installation of a multi-camera system, sensors and local connections, the remote driving experience amplifies the safety and manoeuvrability of operations.

- High definition cameras are installed on each PBB for a complete inside and outside view.

- Images in real-time are necessary for correct operation of the PBB.

- The PBB Docking Assistance Module is included for faster operations.

Remote MARS Operations

Remote operation makes it easy to perform two docking operations at Multiple Aircraft Ramp Systems (MARS) with a single operator.

- The system includes a Handling Communications Unit, which is installed on apron level for communications with apron staff.

- Artificial Intelligence and the PBB Docking Assistance Module allow operators to improve docking operations times by 20%.

Multi-Display and Touch Screen

The size and resolution of the ultra-wide monitor allows the operator to see multiple points of view during an operation. There is also an auxiliary touch screen on the desk for additional features, operating information, control settings, etc.

- ARCOS allows to start the session of each working day for each operator.

- Control passenger boarding bridges with the most decisive points of view in each operation.

- The user interface allows each operation to be performed accurately and safely.

Smooth Controls

The desk includes all the regular controls of a real Airport Passenger Boarding Bridge desk.

- The touch screen allows access to secondary functionalities in each operation.

- Joystick allows precise maneuvers, with smooth movements in every single operation.

- Cabin turn and gantry lift button layout, meets ergonomic standards.

Stand up Position

The height-adjustable desk allows operators to change their working position between sitting and standing, thereby reducing operator fatigue.

- Each operator can set the height of the table before starting their work day.

- The desk is designed to comply with the ergonomic principles and recommendations established by UNE-EN 527-2:2017 and UNE-EN 11064-04:2013..

- The height of the table can be configured through the software.

Dead-man Switch

ARCOS complies with airport security regulations through devices that guarantee that the operator is maneuvering safely.

- Activating the Dead-man switch is an active safety element necessary in every operation.

- The switch is located at the base of the desk, ensuring comfortable use in each operation.

Better qualified personnel leads to lower employee turnover therefore increasing collective experience of operating PBBs and reducing the cost of training new staff. The PBB Docking Assistance Module, allow operators to improve docking time by 20% while avoiding the risk of misoperations that could result in aircraft damage.

The estimated savings in operational costs (OPEX) could be more than 70%, depending on the quantity of PBBs to be operated and the type of airport operations. The estimated time for investment recovery (ROI) is less than two years.

This is a robust, safe and redundant system that represents a step ahead in automation without losing control of the process. ARCOS® redundant security system permanently monitors key system elements that ensure its perfect operation.

ARCOS® includes a Smart Queue Management Module that allows optimization of resources during peak hours. In addition, the module takes into account the productivity of operators, docking times, operating errors, etc. when defining KPIs and establishing improvement processes.

All data collected by ARCOS®, including video recordings, are available to the airport at any time. The continous recording of the inside and outside of the PBB in each operation provides additional security on the apron and its surroundings.

ARCOS® has been verified by Bureau Veritas and Applus+ as compliant with Directive 2006/42/EC on Machinery, making ARCOS® a secure system with all the necessary ISO guarantees to operate PBBs remotely.