ARGOS Gangways specifications

ARGOS está específicamente diseñada para aquellas terminales de pasajeros que desean ofrecer a las líneas de crucero y ferry una forma segura y confortable de llevar a sus pasajeros desde el barco hasta el muelle y viceversa.

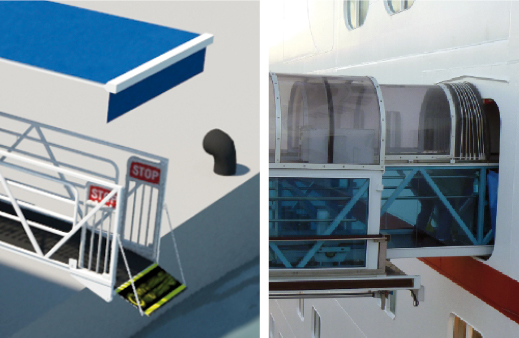

ARGOS está equipada con un sistema de elevación electromecánico, una rampa de embarque hidráulica, sensores de precisión y un Autómata Programable (PLC), que contribuyen a la seguridad y eficiencia de las operaciones de atraque. ARGOS cumple con la mayoría de regulaciones internacionales, como la EN 12312-4.

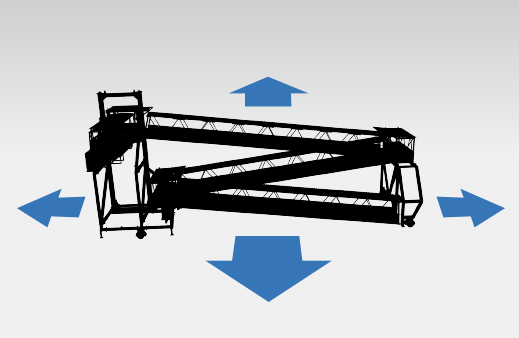

ARGOS se ha diseñado incorporando las últimas innovaciones tecnológicas. La pasarela puede moverse fácilmente a cualquier punto del muelle y se ajusta perfectamente a las distintas ubicaciones de puertas de los navíos. Una vez conectada, ARGOS sigue automáticamente los movimientos del barco y se adapta a las variaciones de marea.

Con unas alturas de atraque máxima y mínima de 9.5 y 1.1 metros sobre el muelle respectivamente, ARGOS proporciona un rango de servicio óptimo, permitiendo atracar una gran variedad de barcos de crucero y ferry, incluidos aquellos con botes salvavidas sobresaliendo del casco.

Suelo antideslizante, pasamanos y pasillos anchos, que permiten el embarque y desembarque simultáneos, hacen de ARGOS una solución ideal para los pasajeros con movilidad reducida.

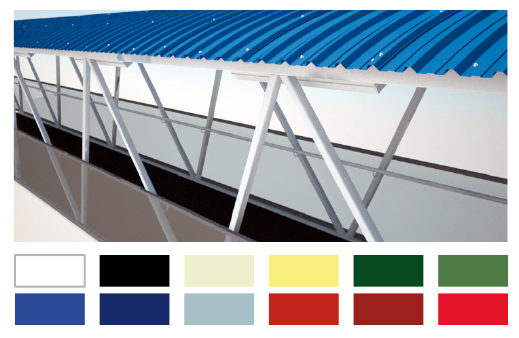

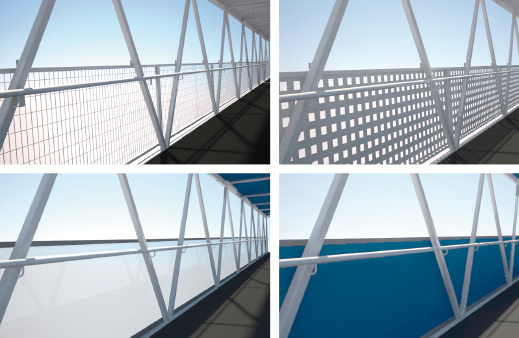

ARGOS incluye de serie un generador eléctrico, pasamanos, iluminación, suelo antideslizante y neumáticos de goma. El diseño puede completarse con un gran abanico de equipamiento opcional: autopropulsión, cubierta, control remoto, anclajes antihuracán y una variedad de acabados.

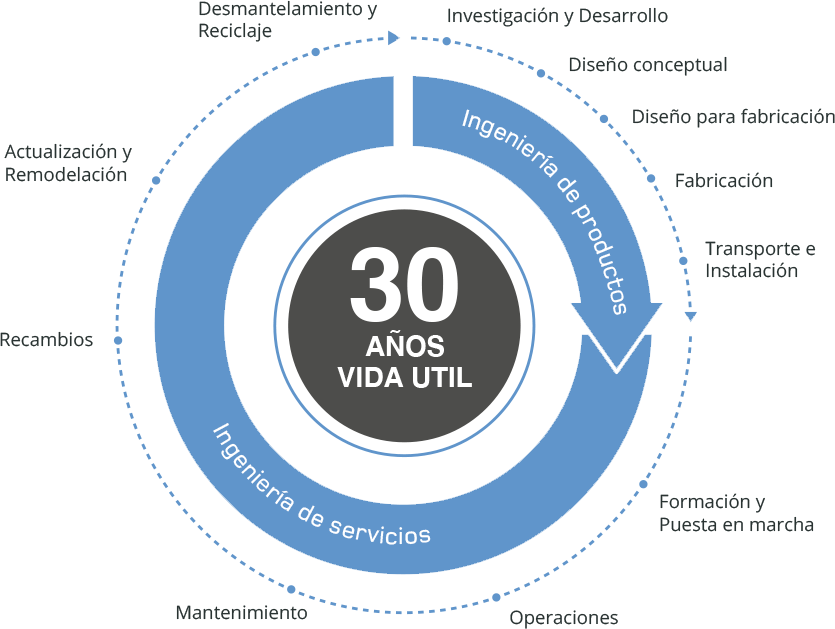

Para ADELTE, garantizar la calidad de sus productos es un imperativo. Todos los materiales se ensayan en condiciones marítimas y siguen un proceso de fabricación certificado que garantiza la durabilidad de todas nuestras pasarelas. Las tareas de mantenimiento pueden realizarse de forma rápida y sencilla gracias al diseño de acceso directo de ADELTE.